BOV (Bag-on-Valve)

Novopharm is a specialist in the development and manufacturing of final medical products using the Bag-On-Valve (BOV) spray technology, is an advanced packaging system and enables the dispensing of liquids, creams, gels, or foams in a more efficient, hygienic, and environmentally friendly way compared to traditional aerosol systems.

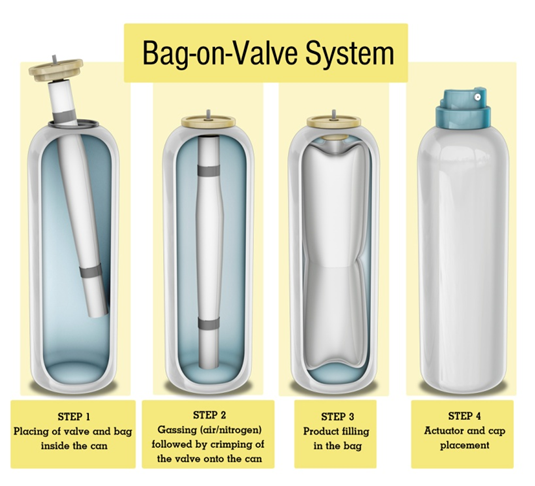

How Bag-on-Valve Technology Works

- Structure:

- The BoV system consists of a flexible bag (typically laminated) inside a can, which is surrounded by compressed gas or air.

- The product (e.g., liquid, cream, or gel) is stored inside the bag, while the pressurized gas remains outside the bag.

- Mechanism:

- When the valve is pressed, the pressurized gas pushes the product out of the bag through the nozzle without mixing with the product.

- Key Components:

- Canister: The outer shell containing the pressurized gas and the bag.

- Bag: Stores the product, ensuring no direct contact with the propellant.

- Valve: Controls the release of the product.

Bag-On-Valve technology is revolutionizing pharmaceutical packaging by enhancing product safety, usability, and environmental sustainability, making it a preferred choice for Novopharm with modern pharmaceutical applications

Advantages

- Preservation of Product Integrity:

-

- The four layers laminate bag offers a superior barrier which eliminates the possibility of contamination, oxidation, or contact with the propellant making it ideal for products of concern.

- Suitable for oxygen- or moisture-sensitive formulations.

- Hygienic and Sterile:

- Ensures the product remains sterile throughout its shelf life, making it ideal for pharmaceuticals like wound sprays, saline solutions, and nasal sprays.

- Consistent Dispensing:

- Provides controlled and uniform dosing without wasting the product.

- Environmentally Friendly:

- Uses compressed air or nitrogen as the propellant, reducing reliance on harmful chemical propellants.

- Extended Shelf Life:

- The sealed system minimizes the risk of microbial contamination, extending product durability.

- Multi-Position Use: 360 Spray from any angle; 360° actuation

-

- Can dispense effectively at any angle, even upside-down, ensuring convenience for the user.

7. Minimized Residue:

-

- The system allows nearly 100% evacuation of the product, reducing waste.

Comparison with Traditional Aerosols

| Feature | Bag-On-Valve | Traditional Aerosol |

| Product Utilization | Nearly 100% | Moderate, with residue |

| Safety | Non-flammable | Flammable due to chemicals |

| Sterility | High | Moderate |

| Environmental Impact | Minimal | High due to Volatile organic compounds (VOCs) |

Specificities

- Net volume: 50-100ml

- Manufacturing capacity: 100,000 units per year

- Application: body acne spray, dry shower spray, osteoarthritis spray...