BFS (Blow – Fill – Seal)

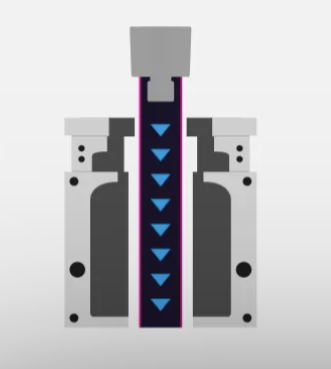

Exrtrusion

Exrtrusion

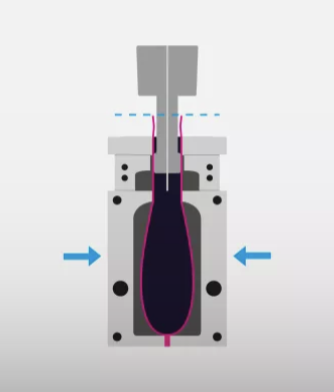

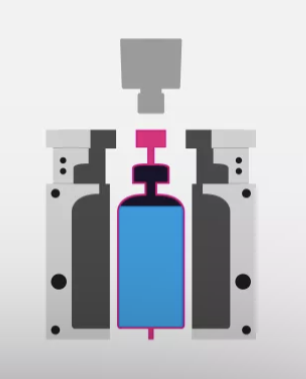

Molding

Molding

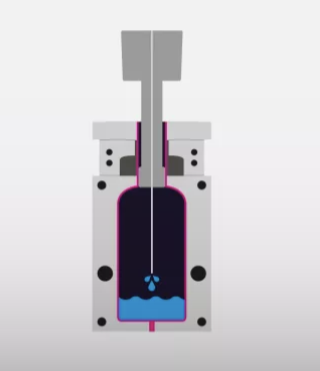

Filling

Filling

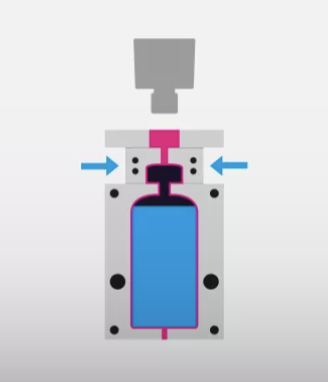

Sealing

Sealing

Demolding

Demolding

Blow-Fill-Seal, commonly abbreviated as BFS, is an advanced technology at Novopharm that guarantees an automated process in which plastic containers (ampoules) are blown, filled, and sealed in a sterile and continuous manner.

BFS technology supports patient safety by offering practical, single-use sterile containers that eliminate the need for preservatives and is recognized by the FDA (US Food and Drug Administration) as a high-end sterile process, for the production of injections/eye drops.

BFS vials are specifically tailored for various pharmaceutical formulations, including solutions, suspensions, gels and emulsions.

There are 3 main stages to produce a product using BFS technology:

Blow: Virgin plastic particles are put into the machine, heated under a temperature of over 160 degrees Celsius and a pressure of 35MPa. Sterile air is blown in, forming a mold for the product packaging.

Fill: The pump pours liquid into the packaging to the correct, full pre-programmed dose.

Seal: After pouring enough dose, the injection pliers are pulled out and the mold is sealed.

Advantages

- Preservative-free single-unit doses

- Ensures that the patient takes the correct amount of product

- Portable and easy to use individually, excellent properties for today’s active lifestyles

- Allows many different container designs, a consistent high process quality, a high process output, and is, compared against other packaging processes, inexpensive.

Specificities

- Capacities: 10.000.000 ampoules/ month

- Volume: 1ml, 2ml, 5ml, 10ml or depends on customer’s demand

- Applications: solutions, suspensions, gels, and emulsions such as: oral liquid (Novita), eye drops (Novotane ultra), topical application (Freeskin Professional control age)